Nelson Lumber Manufacturing

We offer design services for tall walls, all types of floor systems, from manufactured floor trusses, to engineered I-joists. Our design team can assist you at all stages of your custom home construction.

Product Categories

Panelized Walls

Nelson is capable of producing panelized interior and exterior walls for residential and commercial construction to save time on site. A signature product which is also used by our Homes and RTM divisions to drive efficiency and accuracy.

Panels come in pre-built sections, using only top grade lumber, have framed-in window and door openings, and OSB sheathing applied - ensuring quick framing time, lower labour cost and less material waste.

Components are numbered and cross-referenced with the blueprints for quick assembly at your job site.

**Wall Specifications: (jigs all 16’ long) / wall panel jig (1) for framing / wall panel jig (1) for sheeting / rake jig / tall wall jig / partition jig for framing interior walls**

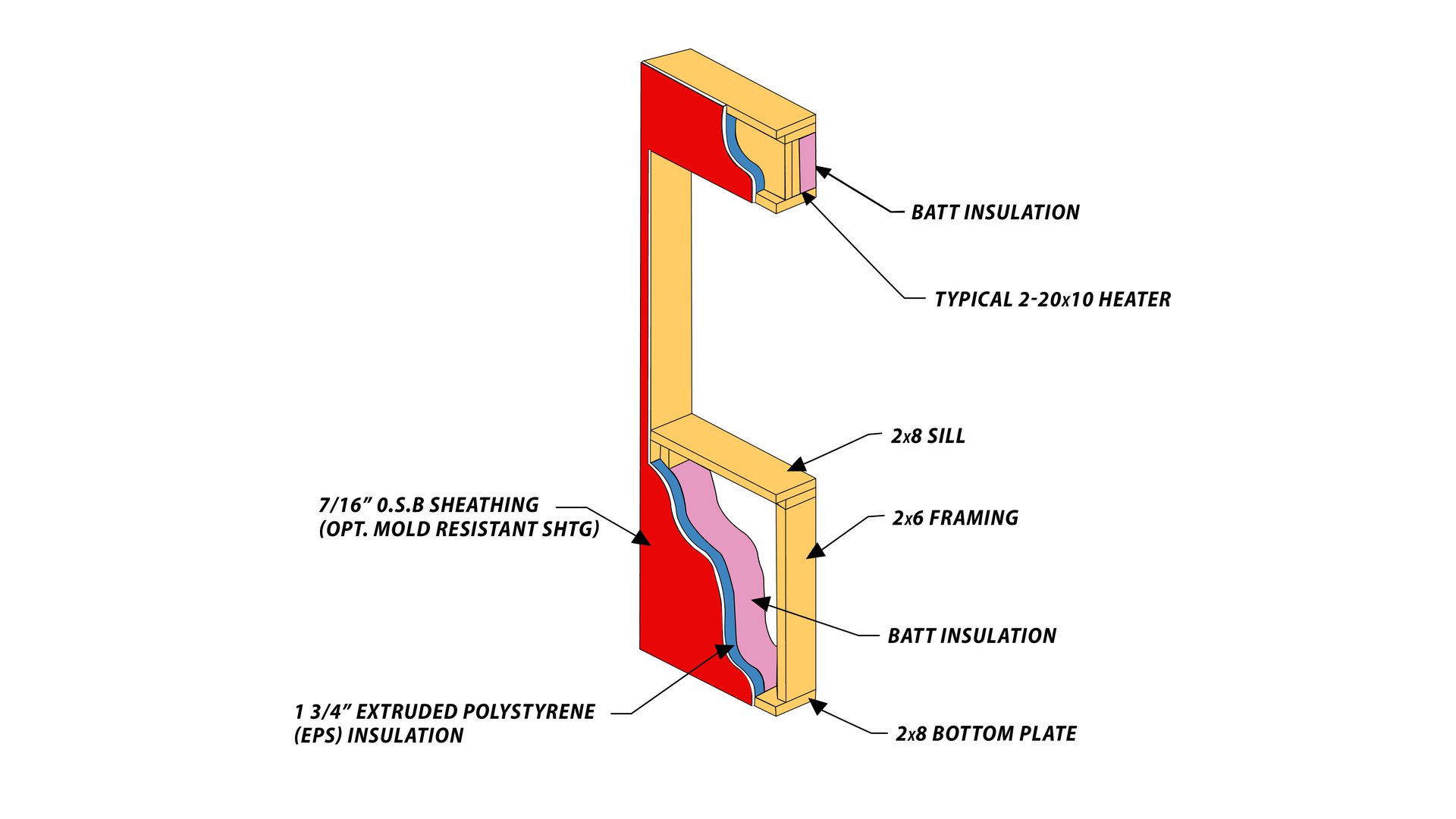

Energy Wall System

Our factory assembled wall system applies a 1 ¾” rigid extruded polystyrene insulation that creates a thermal break (no cold studs). This design reduces heat loss, increases energy saving, increases r-value, and eliminates on-site costs for installing rigid installation. Exterior sheathing allows for easy installation of any siding type. Additionally Nelson Lumber offers optional moisture and mold resistant sheathing.

Building The Energy Wall

Lloydminster Manufacturing Plant

Manufacturing Plant Specifics

With climate controlled manufacturing, lumber remains dry, resulting in straight components due to less warping, twisting and shrinking. That means you'll have less cracks and nail pops and windows and doors will fit properly, thus requiring fewer repairs and adjustments later on. Computer technology ensures that cuts are made precisely and components fit together with great accuracy.